The worldwide lithium-battery market is expected to grow by a factor of 5 to 10 in the next decade, and global demand for Li-ion batteries is expected to soar over the next decade, with the number of GWh required increasing from about 700 GWh in 2022 to around 4.7 TWh by 2030.

- Batteries for mobility applications, such as electric vehicles (EVs), will account for the vast bulk of demand in 2030—about 4,300 GWh.

- Automotive lithium-ion (Li-ion) battery demand increased by about 65% to 550 GWh in 2022, from about 330 GWh in 2021, primarily as a result of growth in electric passenger car sales, with new registrations increasing by 55% in 2022 relative to 2021.

- The global demand for batteries is expected to increase from 185 GWh in 2020 to over 2,000 GWh by 2030.

The battery market is growing at an unprecedented rate, and the electrification of the transportation industry, the use of battery systems to provide energy storage and demand management for the grid, and the batterification of many devices continue to spur this industry’s growth.

However, scaling up lithium-ion battery production to meet the increasing demand faces several challenges, including the availability of raw materials, supply chain disruptions, shortages of labor and materials, gigafactory development, analytical requirements in quality control and monitoring, and environmental concerns.

What are the challenges in scaling up lithium-ion battery production to meet increasing demand?

Scaling up lithium-ion battery production to meet increasing demand faces several challenges that can affect the quality and efficiency of the batteries. Some of the major challenges in scaling up lithium-ion battery production are:

- Availability of raw materials: One of the most significant challenges facing battery manufacturers is the availability of raw materials. The production of lithium-ion batteries relies heavily on the mining of raw materials and the production of the batteries themselves, both of which are vulnerable to supply chain issues that should be addressed during contractual negotiations rather than waiting for the issues to arise during production

- Supply chain disruptions: At each stage of the production process, there are supply chain issues that should be addressed during contractual negotiations rather than waiting for the issues to arise during production

- Shortages of labor and materials: The speed of scaling new technology leads to notable challenges, including shortages of labor and materials, delays in the construction of gigafactories to produce batteries at scale, and competition for resources in the supply chain

- Gigafactory development: Developing gigafactories is challenging, and even the most experienced battery manufacturers commonly encounter difficulties.

Major challenges in the lithium-ion battery production process

The production of lithium-ion batteries faces several challenges that can affect the quality and efficiency of the batteries. Some of the major challenges in the lithium-ion battery production process are:

- Analytical requirements in quality control and monitoring: Quality needs to be monitored at every stage from raw materials through to cell assembly to maintain production efficiency and minimize waste

- Design for manufacture: Efficient and effective manufacture of EV batteries must start with robust design for manufacture (DFM)

- Supply chain disruptions: The lithium-ion battery industry relies heavily on the mining of raw materials and production of the batteries, both of which are vulnerable to supply chain issues that should be addressed during contractual negotiations rather than waiting for the issues to arise during production

- Environmental concerns: The production of Li-ion batteries is resource-intensive and can generate significant environmental impacts

- Expertise: Ensuring reliable batteries requires expertise not only in cell chemistry, electronics, and mechanical engineering but also in other areas

- Flexibility of battery manufacture: The current stage of the industry, with many OEMs working on prototypes, requires flexibility of battery manufacture, in particular, the ability to produce prototypes or small-volume runs

- Vacuum requirements: Vacuum is a critical requirement in every stage of the manufacturing process of lithium-ion batteries, from mixing, drying, filling, degassing up to sealing

Addressing these challenges is crucial to ensure the production of high-quality and efficient lithium-ion batteries.

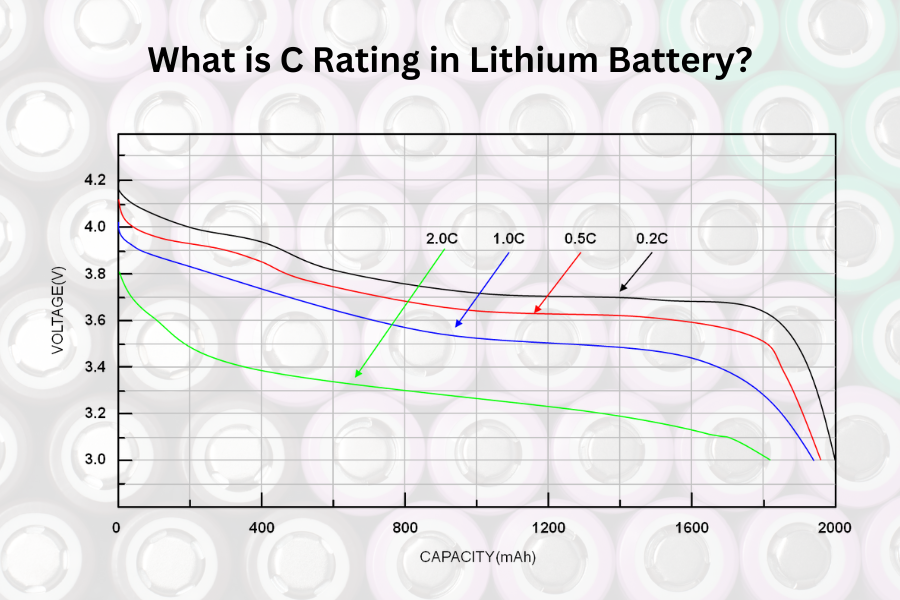

Lithium batteries are cutting-edge energy storage solutions known for their exceptional performance and versatility.