As the demand for efficient and high-performance lithium-ion batteries continues to rise across various industries, the need for effective thermal management strategies becomes increasingly critical.

Thermal management plays a vital role in maintaining battery performance, safety, and longevity, as excessive heat generation can lead to reduced capacity, accelerated aging, and even safety hazards.

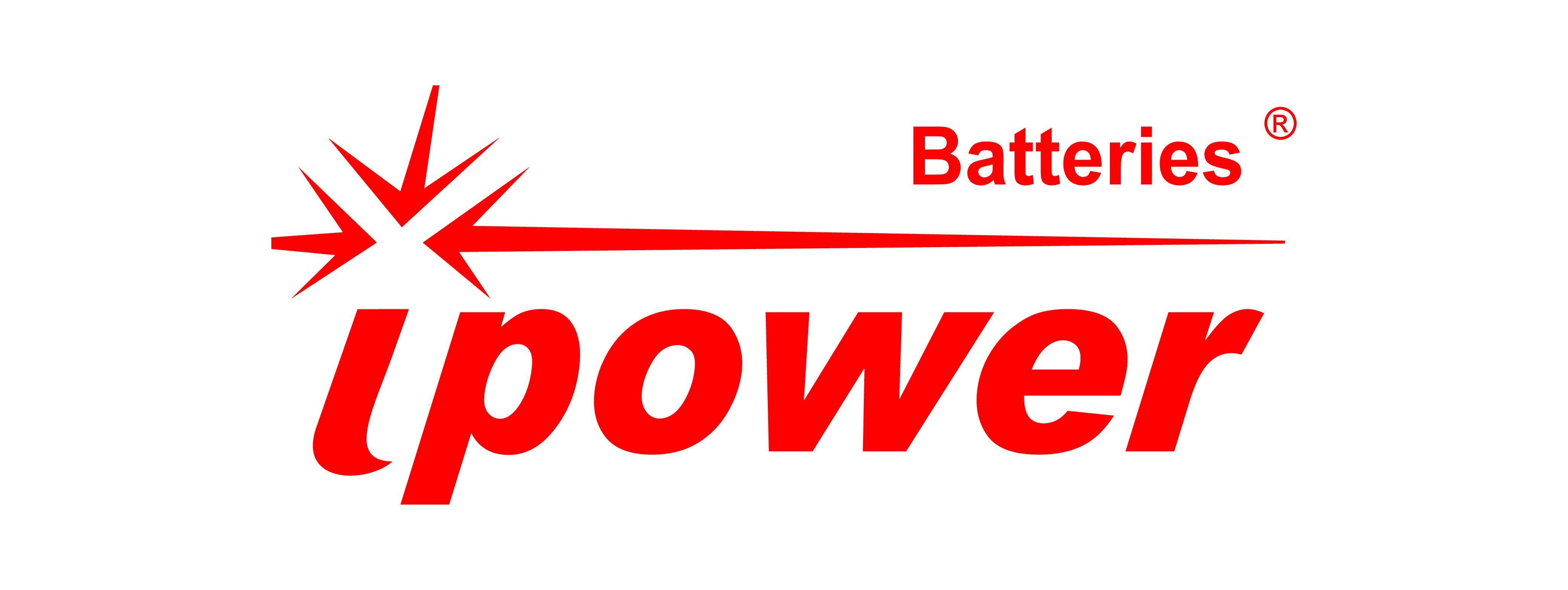

Among the numerous methods employed for thermal management, two prominent options are potting materials and phase change materials (PCMs). While both approaches aim to dissipate heat and regulate the temperature within lithium-ion batteries, they exhibit distinct characteristics that make them suitable for different scenarios.

Potting Materials: Shielding and Insulating

Potting materials are compounds used to encapsulate and shield battery components. These materials are often polymer-based and provide a protective layer around the battery, isolating it from the external environment. The primary purpose of potting materials is to insulate the battery, preventing heat from escaping or entering the battery enclosure. This approach can be effective in maintaining stable operating temperatures, especially when batteries are subjected to fluctuating external conditions. Potting materials can also provide mechanical support, reducing the risk of physical damage to the battery cells.

Advantages of Potting Materials:

- Isolation: Potting materials create a barrier between the battery cells and the surrounding environment, ensuring better thermal insulation.

- Mechanical Protection: The encapsulation offered by potting materials enhances the battery’s resilience against physical stresses and impacts.

- Versatility: Potting materials can be designed to accommodate different battery shapes and sizes.

Phase Change Materials (PCMs): Efficient Heat Absorption

Phase change materials are substances that undergo a phase transition, typically from solid to liquid, in response to temperature changes. These materials have high latent heat capacities, meaning they can absorb and release a significant amount of heat during the phase transition without experiencing a substantial temperature change. PCMs are often integrated into battery packs as passive heat absorbers. When the temperature inside the battery pack increases, the PCM absorbs heat and undergoes a phase transition, effectively moderating the temperature rise within the battery.

Advantages of Phase Change Materials:

- High Heat Absorption: PCMs can absorb and release large amounts of heat during phase transitions, helping to regulate battery temperature effectively.

- Passive Solution: PCMs do not require external power or control systems, making them simple and reliable solutions for thermal management.

- Uniform Temperature: PCMs distribute absorbed heat uniformly, preventing hotspots within the battery pack.

Distinguishing Factors:

While both potting materials and phase change materials offer unique benefits, their differences lie in their primary functions and applicability:

- Objective: Potting materials focus on insulation and protection, while PCMs primarily address heat absorption and temperature moderation.

- Active vs. Passive: Potting materials provide a barrier to heat transfer, requiring an external heat dissipation mechanism. In contrast, PCMs passively absorb and release heat through phase transitions.

- Complexity: Potting materials may involve complex encapsulation processes while integrating PCMs can be relatively straightforward.

- Environmental Factors: Potting materials offer better protection against environmental elements, such as moisture and dust. PCMs are more suitable for internal temperature regulation.

In conclusion, potting and phase change materials contribute to efficient thermal management in lithium-ion batteries, but they serve distinct purposes. Potting materials are geared towards insulation and protection, making them suitable for extreme environmental conditions. On the other hand, phase change materials provide passive heat absorption, maintaining uniform temperatures within the battery pack. The choice between these methods depends on the specific requirements of the battery application, with a consideration of factors such as battery design, operating conditions, and the desired thermal management goals.