Why LMFP is better than LFP and NMC?

Because of their high energy density, long cycle life, and low self-discharge rate, lithium-ion batteries have become the leading energy storage I. technology. The cathode material selected is critical in influencing the overall performance of the battery. This research examines the cathode materials LMFP, LFP, and NMC, emphasizing the merits of LMFP and why it should be considered the ideal choice for lithium-ion battery applications.

In this article, we will explore why LMFP batteries are better than NMC and LFP, especially for the Indian climatic conditions.

- Cathode Material crystal structure

The olivine structure of LMFP and LA’ cathodes provides great thermal stability, long cycle life, and strong safety properties. NMC cathodes, on the other hand, have a layered structure that offers high &clergy density and decent rate capability but may have weaker thermal stability and shorter cycle life.

- Energy density and electrochemical properties

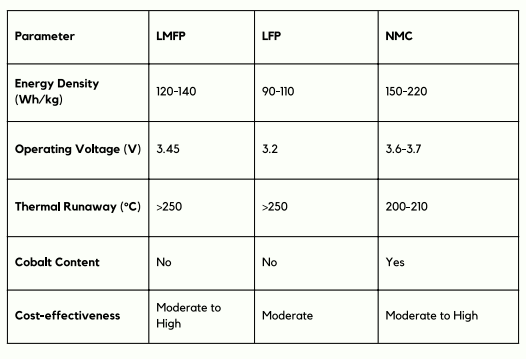

The operating voltage of LMFP is greater (about 3.45V) than that of LFP (approximately 3.2V), resulting in a higher energy density (120-140 Wh/kg for LMFP vs. 9 110 Wh/kg for LA”). This is because manganese is added, which boosts electrical conductivity and lithium-ion diffusion in LMFP. In contrast, NMC has a higher energy density (150-220 Wh/kg) and operating voltage (3.6-3.7V).

- Rate capability

Manganese substitution in LMFP improves lithium-ion diffusion, resulting in higher rate capability compared to LFP. As a result, LMFP is well-suited for high-power applications such as fast-charging electric vehicles and power equipment. Because of its layered structure, which allows for two-dimensional lithium-ion diffusion, NMC also has good rate capability.

- Thermal stability

LMFP retains the thermal stability and safety properties of LFP, with a thermal runaway point above 250°C, making it a safer option than some high-energy-density chemistries such as NMC, which has a thermal runaway point of around 200-210°C.

- Cost & environmental impact

Because iron and manganese are less expensive than cobalt and nickel, LMFP may be more cost-effective than NMC. Furthermore, LMFP is cobalt-free, addressing ethical and environmental concerns about cobalt mining while minimizing reliance on this limited resource.

- Performance in India

The strong thermal stability of lithium manganese iron phosphate makes it a good candidate for Indian temperature conditions, which might be characterised by high ambient temperatures. Its thermal runaway point of more than 250°C delivers good safety performance in the high-temperature environment of India.