Lithium battery pack designing is a topic that involves many aspects, such as cell chemistry, cell configuration, battery management system, safety, and performance.

In this blog, we will give you an overview of some of the key factors that you need to consider when designing a lithium battery pack for your electric vehicle or other applications.Type of Lithium Cells

Lithium-ion batteries are made of cells that store and release energy by moving electrons and ions between two electrodes, an anode, and a cathode, through an electrolyte and a separator. The anode is the negative electrode that gives out electrons, while the cathode is the positive electrode that receives electrons. The electrolyte is a liquid or solid substance that enables the flow of ions between the electrodes. The separator is a thin membrane that keeps the electrodes from touching and causing a short circuit. The type of cells that you choose for your battery pack depends on your application and the characteristics that you want your battery pack to have.Different types of cells have different pros and cons in terms of energy density, power density, cycle life, safety, cost, and environmental impact.

Lithium cobalt oxide (LCO): This is one of the most widely used types of cells for consumer electronics, such as laptops and smartphones. It has a high energy density, but a low power density and a short cycle life. It is also very sensitive to overcharging or damage and can cause thermal runaway and fire.

Lithium manganese oxide (LMO): This is a safer and cheaper alternative to LCO but with a lower energy density and a higher self-discharge rate. It is often used for power tools and electric bikes.

Lithium nickel manganese cobalt oxide (NMC): This is a popular type of cell for electric vehicles, as it offers a good balance of energy density, power density, cycle life, and safety. It is also more stable and less expensive than LCO.

Lithium iron phosphate (LFP): This is a very safe and long-lasting type of cell but with a low energy density and a high weight. It is suitable for applications that require high power and long cycle life, such as stationary energy storage and electric buses.

Lithium nickel cobalt aluminum oxide (NCA): This is a high-performance type of cell that has a high energy density and a high power density, but a low cycle life and a high cost. It is mainly used by Tesla for its electric vehicles.

Lithium titanate (LTO): This is a unique type of cell that has a very high power density and a very long cycle life, but a very low energy density and a very high cost. It is ideal for applications that require fast charging and high power, such as electric buses and grid storage.

Cell configurationOnce you have chosen the cell chemistry, you need to decide how to arrange the cells in the battery pack. The cell configuration determines the voltage, capacity, and current of the battery pack. There are two ways to connect the cells: in series or parallel.

Series connection: This means connecting the positive terminal of one cell to the negative terminal of another cell. This increases the voltage of the battery pack but keeps the capacity and current the same as a single cell. For example, if you connect four 3.6 V cells in series, you get a 14.4 V battery pack with the same capacity and current as one cell.

Parallel connection: This means connecting the positive terminals of multiple cells, and the negative terminals of multiple cells. This increases the capacity and current of the battery pack but keeps the voltage the same as a single cell. For example, if you connect four 3.6 V cells in parallel, you get a 3.6 V battery pack with four times the capacity and current of one cell.

You can also combine series and parallel connections to achieve the desired voltage, capacity, and current of the battery pack. For example, if you connect four 3.6 V cells in series, and then connect four of these series strings in parallel, you get a 14.4 V battery pack with four times the capacity and current as one cell.The cell configuration also affects the size, weight, and shape of the battery pack. You need to consider the available space, the mechanical strength, and the thermal management of the battery pack when designing the cell configuration.

Safety among Lithium Batteries

Safety is the most important aspect of lithium battery pack designing, as lithium-ion batteries can pose a fire and explosion hazard if not handled properly. Several factors can cause a lithium-ion battery to fail, such as:· Manufacturing defects, such as impurities, cracks, or metal particles in the cells

· Mechanical damage, such as punctures, crushes, or drops

· Electrical abuse, such as overcharging, over-discharging, short circuit, or reverse polarity

· Thermal abuse, such as overheating, overcooling, or exposure to fire

· Environmental factors, such as humidity, pressure, or vibration

To prevent or mitigate these risks, you need to follow some best practices when designing a lithium battery pack, such as:

· Choosing a suitable cell chemistry that matches the application and the safety requirements

· Using high-quality cells from reputable manufacturers that have passed rigorous testing and certification

· Designing a robust cell configuration that can withstand mechanical and thermal stress

· Incorporating a reliable BMS that can monitor and protect the battery pack from electrical and thermal abuse

· Adding safety features, such as fuses, circuit breakers, diodes, switches, vents, and flame retardants

· Testing and validating the battery pack under various conditions and scenarios

· Following the standards and regulations for lithium battery pack design, transportation, and disposal

Performance of Lithium batteriesPerformance is another important aspect of lithium battery pack design, as it determines the functionality and efficiency of the battery pack. Several parameters measure the performance of a lithium battery pack, such as:

· Energy density: This is the amount of energy stored per unit volume or weight of the battery pack. It affects the range and endurance of the battery pack. The higher the energy density, the longer the battery pack can run.

· Power density: This is the amount of power delivered per unit volume or weight of the battery pack. It affects the speed and acceleration of the battery pack. The higher the power density, the faster the battery pack can operate.

· Cycle life: This is the number of times the battery pack can be charged and discharged before its capacity drops below a certain threshold. It affects the lifespan and durability of the battery pack. The longer the cycle life, the more the battery pack can be used.

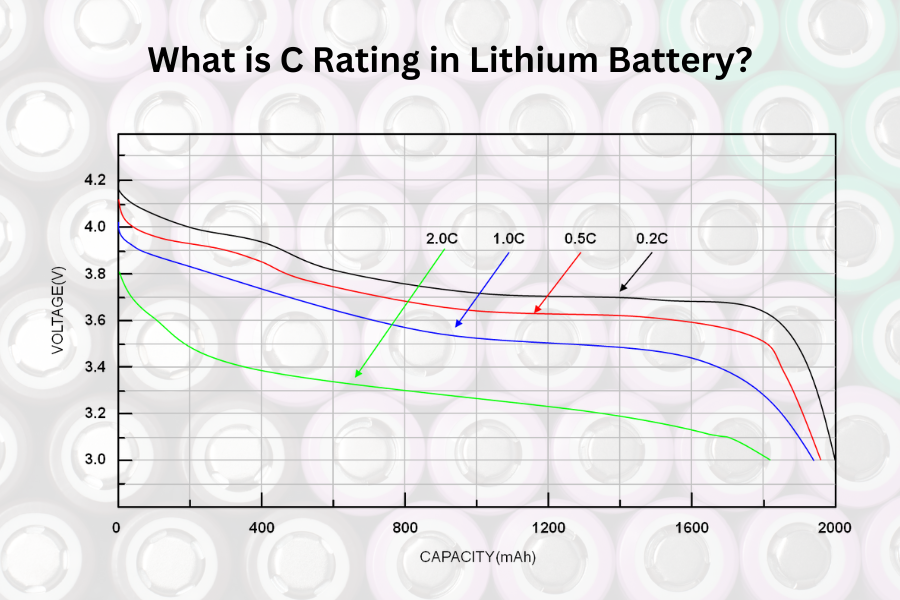

· Charge and discharge rate: This is the speed at which the battery pack can be charged and discharged. It affects the convenience and flexibility of the battery pack. The faster the charge and discharge rate, the less time the battery pack needs to be plugged in or out.

· Self-discharge rate: This is the rate at which the battery pack loses its charge when not in use. It affects the storage and maintenance of the battery pack. The lower the self-discharge rate, the longer the battery pack can retain its charge.

To optimize the performance of the battery pack, you need to consider the trade-offs and compromises between these parameters, as well as the application and the user requirements. For example, if you are designing a battery pack for an electric car, you may want to prioritize energy density and cycle life overpower density and charge rate, while if you are designing a battery pack for a drone, you may want to prioritize power density and charge rate over energy density and cycle life.