Discover how an Energy Storage System keeps businesses running during power cuts with stable backup, smart power management, and efficiency.

The New Ipower Battery Is Here: Here’s What You Should Know

Discover the new Ipower Lithium Ion Battery for Inverter with fast charging, smart BMS, app monitoring, and 5-year warranty. Reliable home backup.

The Role of Lithium-Ion Batteries in Industrial and commercial Inverters

Think of those unproductive days when the lights go out mid-shift? Machines stop. Deadlines slip away. Everyone panics. That’s exactly why a commercial inverter battery is more than a backup; it’s a lifesaver and backbone of your business productivity.

However, with time, the relevant upgrade in technology, lithium-ion batteries are changing the game.

Ipower is a lithium-ion battery manufacturer. We are advancing technology to innovate our applications. This helps your business grow across various sectors and industries.

In this blog, let’s understand how Lithium-Ion Batteries are game changers in Commercial and Industrial Inverters.

Why Lithium-Ion Batteries Make a Difference

Traditional batteries in 2026? They drain fast. Heavy loads? They struggle. Maintenance? A lot more concerning questions; however, they were perfectly relevant in simpler times.

However, Lithium-ion? Completely different story. Charges fast. Steady voltage. Low fuss. You will notice the difference almost immediately.

At Ipower, our Lithium-Ion Industrial and Commercial Inverter battery handle real-world industrial stress. Smart monitoring tracks temperature, load, and performance. It’s like the battery is quietly taking care of itself. You can almost forget it’s even there… until you need it to save the day.

Reliability You Can Count On

Downtime is expensive. Not just in terms of money, but your business reputation, workflow, and client trust can all be at stake, all hit when power fails. Lithium-ion batteries last thousands of cycles before showing wear. leads to fewer replacements. Less stress. Smooth operations.

Ipower ensures industrial and commercial Inverter batteries meet safety and regulatory standards. Safe power isn’t optional when businesses and industries operate with thousands of people.

Efficiency, Space, and Flexibility: Industries And Commercial Inverter Battery

Space is tight in most commercial and industrial setups. Lithium-ion batteries are compact. Modular too. Need more capacity later? Just add modules. No tearing down walls. No rewiring nightmares.

Efficiency improves too. Voltage stays steady. Energy loss drops. Sensitive equipment stays protected. It’s like having a spare engine ready before your car breaks down. Quiet. Reliable. Ready to jump in whenever needed.

Why Ipower Stands Out

Ipower doesn’t supply batteries. We deliver solutions that last. Each Industrial and commercial Inverter battery undergoes rigorous industrial testing. Longevity, efficiency, safety, they’re built in. Businesses notice.

Last Thought

Lithium-ion batteries have completely redefined commercial and industrial inverters. Efficient. Reliable. Scalable. With Ipower’s commercial inverter batteries, businesses get consistent power, protected equipment, and operational confidence. And that’s what really matters in the long run.

Curious about how Ipower’s Industrial and commercial Inverter battery can boost your energy efficiency?

Explore our full range of commercial energy solutions and see how we can help optimize your business’s power systems

FAQs

Q1. Why choose lithium-ion batteries for industrial and commercial inverters?

Industrial and commercial inverter battery charges faster, last longer, and maintain stable voltage under heavy loads.

Q2. Are they safe for industrial setups?

Absolutely. Smart monitoring keeps temperature, load, and performance in check.

Q3. Can I expand the system later?

Yes. Modular design allows scaling easily as energy needs grow.

The Future of Urban Mobility: How EVs and E-Rickshaws Are Shaping Indian Cities

Reliable EV batteries by Ipower. Durable, efficient, and designed for real Indian urban conditions powering e-rickshaws and EVs daily.

Can Residential ESS Help You During Power Outages? Here’s What You Need to Know

Ipower, a trusted Energy Storage System Supplier, offers reliable residential ESS for backup power, energy independence, and intelligent energy management.

How Battery Chemistry, Heat, and Usage Habits Impact E-Rickshaw Battery Life in India

Learn how Lithium Ion Batteries for E Rickshaw perform better in Indian heat, usage conditions, and daily charging cycles.

Optimizing Lithium-Ion Batteries for E-Rickshaws: Challenges, Innovations, and Practical Insights

Learn how Lithium Ion Batteries for E Rickshaws improve range, safety, and cost efficiency with smart BMS, thermal control, and innovations.

Mistakes EV Buyers Make When Choosing a Battery

Learn common EV battery mistakes and why choosing the right EV battery manufacturer in India matters for better performance, safety, and income.

Why Lithium Ion Batteries Are the Smart Power Choice for E-Rickshaws in India

With India’s increasing population, E-rickshaws do not have an easy workday. They stop, start, carry weight, recharge, and repeat, often for hours without a break. Over time, it becomes clear that performance issues are rarely about the motor or the controller. More often, they trace back to the battery..

This is why choosing the right lithium ion battery for e rickshaw in India directly impacts daily earnings and long-term reliability.

At Ipower, this shift has been visible for years. As a Lithium Ion Battery Manufacturer in India, the company designs batteries around how e-rickshaws actually function on Indian roads.

In this blog, let’s cover the reasons why Lithium ion batteries are the smart power choice for E-rickshaw in India.

Why Traditional Batteries Fall Short for E-Rickshaws

Conventional battery systems struggle under repetitive charging cycles and long operating hours. Heat builds up. Voltage drops. Maintenance becomes frequent. Gradually, range shortens, and downtime increases.

Lithium-ion technology approaches the problem differently. A Lithium Ion Battery for E Rickshaw delivers stable voltage throughout discharge and charges more efficiently. As a result, drivers experience consistent pickup and predictable range, even during long shifts.

That consistency matters more than peak numbers on a data sheet.

Efficiency Benefits of Lithium Ion Battery for E Rickshaw

Lithium-ion batteries convert energy more effectively and efficiently. They waste less power as heat and respond better to frequent acceleration and braking. Additionally, their lighter weight reduces the overall vehicle load.

Therefore, E-rickshaws run smoother and travel farther on a single charge.

For fleet owners, this means fewer charging intervals hence, better route planning. In daily operations, those small gains add up quickly.

Longer Lifespan of Lithium Ion Battery for E Rickshaw

Battery replacement is one of the biggest cost concerns in electric mobility. Lithium-ion batteries address this concern directly. They support a higher number of charge cycles and maintain capacity longer.

A well-engineered Lithium Ion Battery for E Rickshaw also requires less maintenance There is no memory effect. Performance does not degrade abruptly. Instead, it declines gradually and predictably.

This reliability reduces lifetime operating costs and improves overall asset planning.

Safety Is Designed, Not Assumed

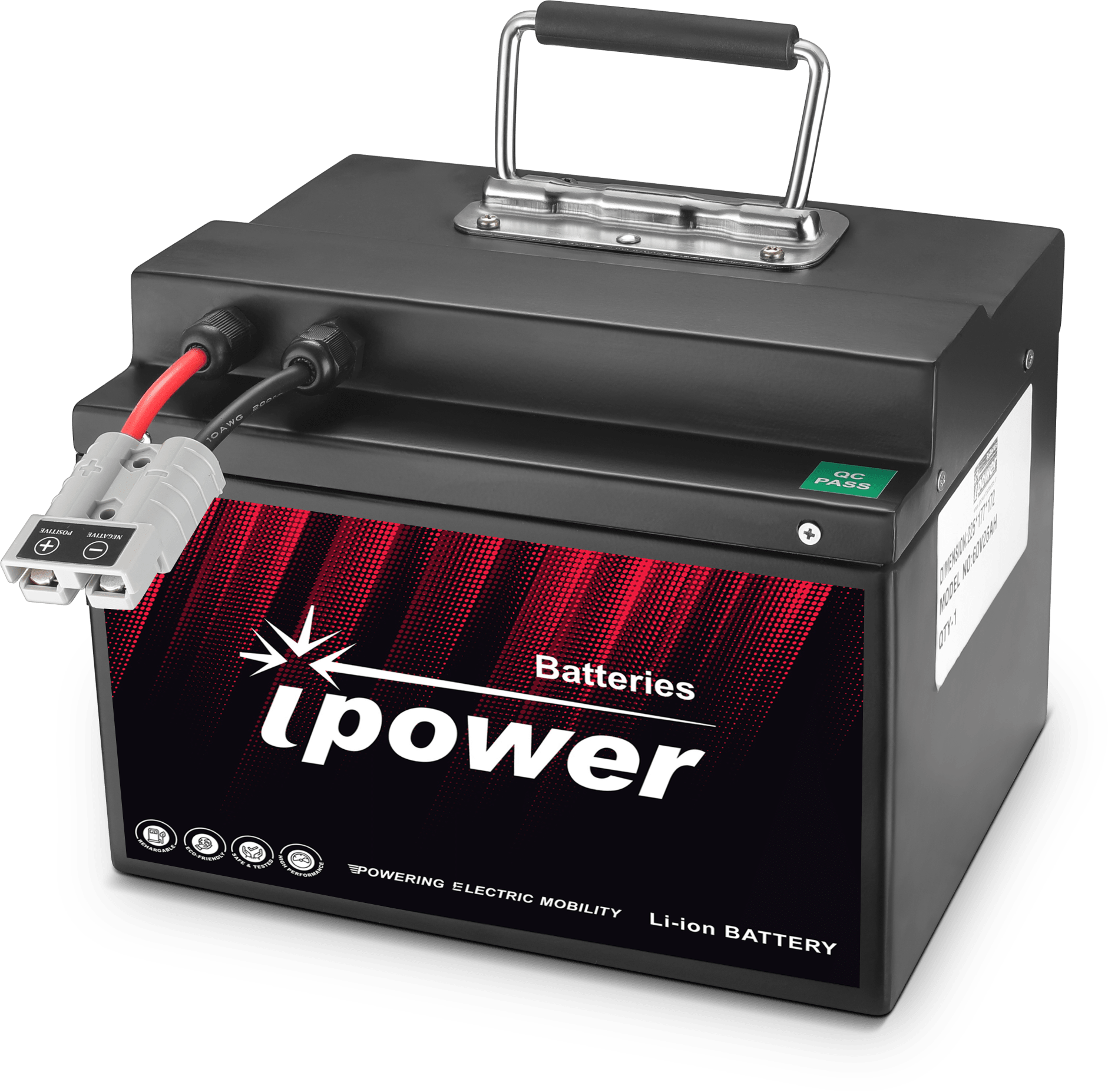

Lithium-ion safety depends on control. At Ipower, every Lithium ion battery integrates an advanced Battery Management System. The system continuously monitors temperature, voltage, and current and intervenes when limits are exceeded.

Because of this, risks related to overcharging, overheating, and electrical faults reduce significantly. In crowded urban environments, this level of protection is essential.

Ipower’s Application-Driven Manufacturing Approach

Ipower does not build generic battery packs. Each Lithium Ion Battery for E Rickshaw is designed around real load conditions, driving patterns, and charging behaviour.

As a Lithium Ion Battery Manufacturer in India, the company tests its batteries under practical scenarios, not ideal laboratory assumptions. This approach ensures consistency, durability, and dependable performance over time.

Conclusion

E-rickshaw battery requirements need to meet day-to-day operational needs. Lithium ion batteries for e- rickshaws provide these operational requirements by providing a more efficient product, longer lifespan, and a greater degree of controlled safety.

To combine disciplined manufacturing processes with intelligent use of battery management, Ipower provides real-world endurance solutions to end users. When making decisions regarding reliability and long-term value, users can rely upon lithium-ion technology.

If you are looking out for high-quality lithium-ion batteries for your e-rickshaw, explore our lithium-ion solutions designed to meet diverse power requirements. https://ipowerbatteries.in/

FAQ

Q1. Does a lighter lithium ion battery really matter for e-rickshaws?

Yes. Less weight means the vehicle runs more easily and goes a bit farther on each charge.

Q2. Can I charge it multiple times in a day?

Yes. Short and frequent charging won’t damage the battery, which is useful during busy workdays.

Q3. How do Ipower’s High-quality lithium ion batteries make the difference?

Because a poorly made battery causes breakdowns, loss of range, and safety problems. Good design avoids all that.

Why Lithium ion ESS Or Energy Storage System Battery Is a Smart Investment for Commercial Establishments

Save on electricity, protect equipment, and go green with a reliable energy storage system battery for commercial establishments.

From Backup Power to Profit Center: How Commercial ESS Is Transforming Modern Businesses

Discover how a professional Energy Storage System Supplier like Ipower helps businesses cut energy costs, improve reliability, and generate profit with ESS.

The Role of Battery Management Systems in Enhancing the Life Cycle of Lithium Ion Batteries

Ipower, a trusted lithium-ion battery manufacturer in India, ensures long battery life with advanced BMS technology for electric vehicles, solar, and more.

Top Signs Your E-Rickshaw Needs a New Battery And How to Choose the Right One

Discover lithium-ion e rickshaw batteries for long backup, fast charging and daily performance. Learn signs to replace and choose the right battery.

How Ipower’s Lithium-Ion Batteries Are Shaping Cleaner, Smarter Travel

Ipower is a lithium ion battery manufacturer in India delivering reliable batteries for e-rickshaws, two and three wheelers for cleaner urban travel!!

Smart BMS & IoT in E-Rickshaw Batteries: What Drivers Must Know From Electric Rickshaw Battery Manufacturer In India

Explore how Smart BMS & IoT from an electric rickshaw battery manufacturer in India like Ipower enhance battery life, safety, and driver earnings.

How Electric Rickshaw in Delhi Is Filling the Gap in Last-Mile Connectivity

Learn how Lithium-Ion Battery for E-Rickshaw improves last-mile connectivity in Delhi with longer range, fast charging, and reliable daily performance.

How ESS Helps Manufacturing Units Cut Energy Costs and Boost Productivity

Ipower Batteries, an Energy Storage System Supplier, offers High Voltage ESS to reduce energy costs and boost productivity for manufacturing units.

How to Choose the Right Residential ESS for Your Home

Choose the right residential ESS with guidance from a trusted Energy Storage System Supplier offering safe, smart, reliable lithium solutions.

How Better Battery Design Is Changing the E-rickshaw Market

Ipower, a leading EV battery manufacturer in India, offers lithium-ion e-rickshaw batteries with smart BMS, fast charging, higher range, and AIS-156 safety.

Residential ESS: Smart and Dependable Energy Storage for Your Home

Ipower Residential ESS provides smart, reliable home energy storage with solar and grid support. Save costs, reduce outages, and enjoy clean, steady power.

Where Reliability Meets Innovation: Ipower Energy Storage System Built for Commercial Purpose

Choose Ipower, one of the top ESS manufacturers in India, offering reliable, customizable energy storage systems for commercial and industrial power needs.

The Rise of Residential ESS: Smarter Home Energy for a Growing India

Explore Ipower’s Residential ESS. Save on bills, reduce outages, and optimize solar energy use for smarter, more efficient homes with advanced ESS solutions.

Why Investing in High-Quality EV Batteries Pays Off in the Long Run

High-quality EV batteries deliver longer life, better range, safety, and lower maintenance, helping commercial EV drivers save money and earn more every day.

How to Select the Best Battery for Your Electric Vehicle

Ipower Batteries offers long-lasting, safe EV batteries for E-rickshaws and 2-wheelers, providing better range, strong durability, and smooth daily use.

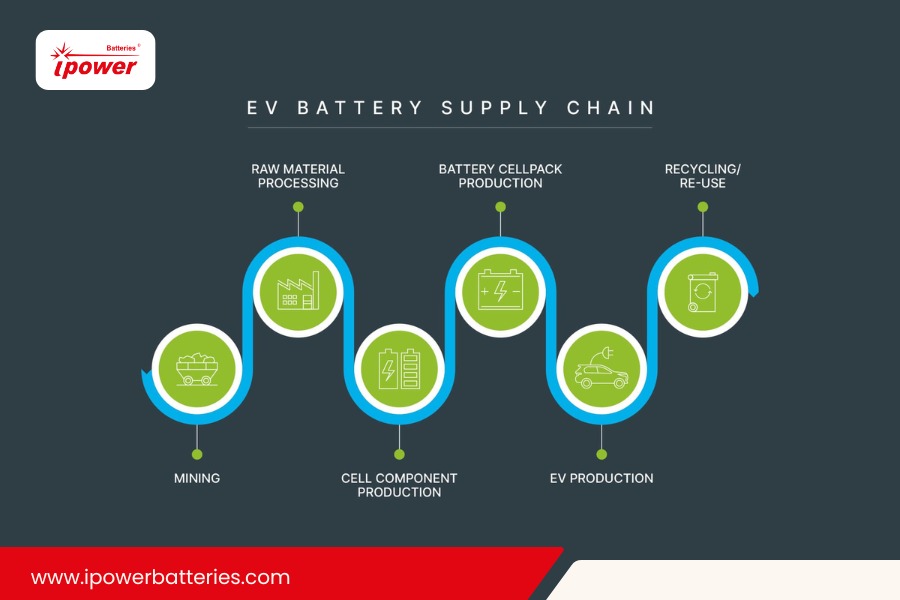

Importance of EV Battery Supply Chain Sustainability in the Global Market

The electric vehicle (EV) industry is at the forefront of global efforts to decarbonize transportation, but its sustainability extends beyond just zero-emission driving. One of the most critical yet often overlooked aspects of the EV ecosystem is the sustainability of its battery supply chain. From raw material extraction to battery recycling, ensuring a sustainable supply chain is key to minimizing environmental impact, reducing costs, and securing long-term availability of essential materials.

Environmental Impact of EV Battery Production

Lithium-ion batteries, the backbone of EVs, require key raw materials such as lithium, cobalt, nickel, and graphite. Extracting these materials has significant environmental consequences, including deforestation, water contamination, and carbon emissions. Sustainable sourcing of these raw materials is essential to reducing the ecological footprint of EV production. Ethical mining practices, efficient resource extraction, and alternative material innovations can mitigate environmental damage while ensuring continued supply.

Ethical and Social Considerations

Many of the materials used in EV batteries come from regions with poor labor conditions and human rights violations. Cobalt mining in the Democratic Republic of the Congo (DRC), for example, has been linked to child labor and hazardous working conditions. Ensuring sustainability in the supply chain means adopting fair labor practices, enforcing corporate social responsibility (CSR) policies, and increasing transparency in sourcing. Initiatives like blockchain-based tracking systems and industry-wide certifications can help address these ethical concerns.

Geopolitical Risks and Supply Chain Resilience

The global battery supply chain is highly dependent on a few key regions for raw material extraction and processing. China dominates the lithium refining and battery manufacturing sector, while Africa and South America are major sources of raw materials. This concentration creates geopolitical risks and supply vulnerabilities. Diversifying sourcing strategies, developing domestic refining capabilities, and promoting circular economies through recycling can enhance supply chain resilience and reduce dependence on a single country or region.

The Role of Recycling and Second-Life Batteries

A sustainable battery supply chain must prioritize end-of-life solutions. Recycling spent EV batteries helps recover valuable materials, reducing the need for virgin resource extraction. Second-life applications, where EV batteries are repurposed for energy storage, further extend their lifecycle before recycling. Implementing robust recycling infrastructure and incentivizing manufacturers to adopt closed-loop systems are crucial for minimizing waste and optimizing material use.

Innovations in Sustainable Battery Technology

Advancements in battery chemistry and manufacturing techniques play a significant role in sustainability. Researchers are exploring alternatives to lithium-ion technology, such as solid-state batteries, sodium-ion batteries, and lithium-sulfur batteries, which promise improved energy efficiency and reduced reliance on scarce materials. Green manufacturing practices, including energy-efficient production processes and low-carbon battery production, also contribute to a more sustainable supply chain.

Policy and Industry Collaboration

Governments and industry stakeholders must work together to establish regulations and incentives for a greener EV battery supply chain. Policies like the European Union’s Battery Directive and the U.S. Inflation Reduction Act include provisions for responsible sourcing, sustainability reporting, and recycling mandates. Industry collaborations, such as partnerships between automakers and battery producers, can drive innovation and create more transparent, accountable supply chains.

The transition to electric mobility is a crucial step toward reducing global carbon emissions, but achieving true sustainability requires a holistic approach to the EV battery supply chain. From ethical sourcing and environmental conservation to recycling and technological advancements, every aspect of the supply chain must be optimized for long-term viability. By prioritizing sustainability, the global EV market can ensure a stable, responsible, and efficient battery ecosystem that supports the broader goals of clean transportation and environmental stewardship.

Difference Between Locally Manufactured Li Battery Pack and a High-Quality Battery Pack

In today’s rapidly evolving electric vehicle (EV) and energy storage market, lithium-ion (Li-ion) battery packs play a crucial role in determining the efficiency, longevity, and performance of a system. While the market is flooded with locally manufactured Li-ion battery packs, not all of them meet the high standards required for superior performance, safety, and durability.

Quality of Battery Cells

One of the biggest differentiators between locally manufactured and high-quality battery packs is the quality of battery cells used. Many local manufacturers source cells from unreliable or unverified suppliers, leading to inconsistencies in performance. In some cases, recycled or second-hand cells are used, which significantly reduces battery life and efficiency. Lower-grade cells with poor energy density and shorter cycle life further diminish the reliability of these battery packs. On the other hand, high-quality battery packs source grade-A lithium cells from reputed manufacturers, ensuring consistency, optimal energy density, and longevity.

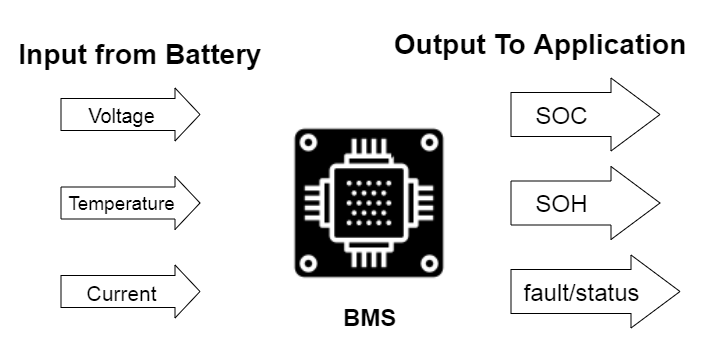

Battery Management System (BMS)

Another key aspect is the Battery Management System (BMS). Many locally manufactured packs come with a basic or unoptimized BMS, leading to inefficient charge-discharge cycles. Poor thermal management can cause overheating, increasing the risk of fire hazards and battery degradation. In contrast, a well-integrated BMS ensures real-time monitoring of temperature, voltage, and current, preventing overcharging and improving the overall lifespan of the battery pack. Advanced balancing features optimize performance and ensure the longevity of each cell.

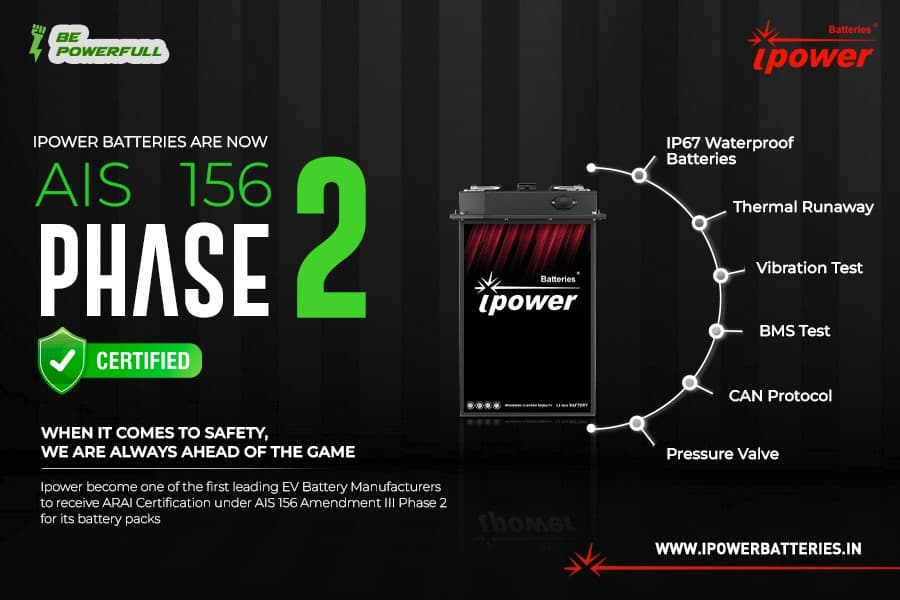

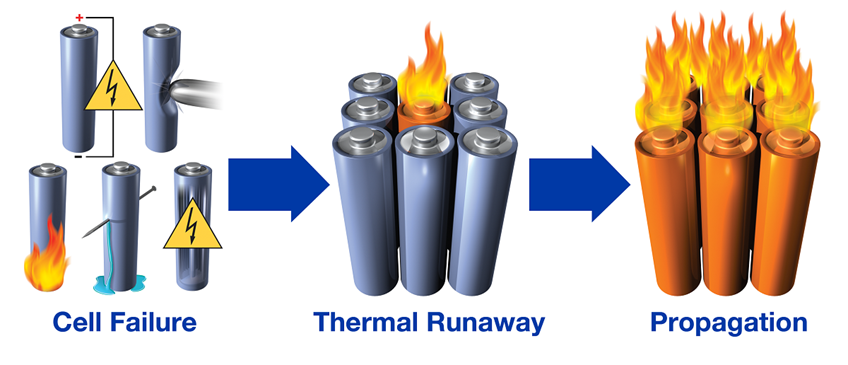

Safety Standards and Certifications

Safety standards and certifications also play a significant role in battery reliability. Many local manufacturers do not comply with international safety standards, making their battery packs prone to thermal runaway or short circuits. The lack of comprehensive safety testing often results in battery failures under harsh conditions. In contrast, high-quality battery packs adhere to strict safety regulations and undergo rigorous testing for thermal, vibration, impact, and short-circuit resistance, ensuring reliability for automotive, industrial, and energy storage applications.

Customization and Scalability

Customization and scalability are other aspects where locally manufactured battery packs often fall short. Many of these packs are designed for generic applications, offering limited customization options. As a result, businesses struggle to find tailored solutions that meet their specific needs. Additionally, scaling up production with locally manufactured battery packs can be a challenge due to inconsistent supply chain management. On the other hand, premium battery packs provide customized solutions for various applications, such as EVs, solar energy storage, and industrial automation, while maintaining high production scalability.

After-Sales Support and Warranty

After-sales support and warranty also differentiate high-quality battery packs from locally manufactured ones. Many local manufacturers do not provide long-term warranty support, and their technical support and servicing are often unreliable or unavailable. Replacement parts are difficult to source, leading to downtime and increased maintenance costs. In contrast, premium battery packs come with industry-leading warranty periods and dedicated customer support. Availability of replacement parts and easy repair options minimize downtime and enhance long-term cost-effectiveness.

Performance and Lifecycle

Performance and lifecycle also show a stark contrast between the two. Locally manufactured battery packs typically have shorter life cycles due to low-quality cells and improper BMS integration. High internal resistance leads to energy losses and lower efficiency, while performance degrades quickly under extreme temperatures. On the other hand, high-quality battery packs are designed for extended cycle life with superior cell chemistry and optimized BMS, ensuring efficiency, power output, and stability even in extreme environmental conditions.

With the growing demand for reliable energy storage solutions, choosing the right lithium-ion battery pack is critical. While locally manufactured battery packs may offer a cost advantage, their reliability, safety, and efficiency often fall short. Investing in a high-quality battery pack ensures better performance, safety, and long-term cost savings, making it the preferred choice for electric vehicles, solar storage, and industrial applications.

Key Advancements in Lithium Battery Cooling Technologies for Enhanced Performance

Lithium battery cooling technologies have become a focal point in advancing energy storage solutions. As lithium-ion batteries power devices ranging from smartphones to electric vehicles (EVs), the need for effective thermal management has never been more critical. These technologies ensure optimal performance, safety, and longevity by mitigating overheating and preventing thermal runaway. This article explores the latest innovations in lithium battery cooling technologies and their role in enhancing performance and safety.

Why Lithium Battery Cooling Technologies Are Essential

Efficient cooling systems are indispensable for maintaining the ideal temperature range in lithium-ion batteries. Overheating can lead to reduced efficiency, shorter battery life, and safety risks such as thermal runaway. Advancements in lithium battery cooling technologies are addressing these challenges, enabling high-performance and safer applications in energy storage systems.

Breakthroughs in Lithium Battery Cooling Technologies

1. Advanced Air-Cooling Systems

Air-cooling systems are cost-effective and simple, making them popular for various applications. Recent designs focus on optimizing airflow patterns, ensuring uniform temperature distribution and effective heat dissipation. This ensures that lithium battery cooling technologies meet the growing demands of modern applications.

2. Efficient Liquid-Cooling Systems

Liquid-cooling systems offer superior heat transfer capabilities, making them ideal for high-power batteries used in EVs. Advanced designs now incorporate hybrid approaches that combine liquid cooling with other technologies to enhance thermal regulation. These innovations highlight the adaptability of lithium battery cooling technologies in diverse environments.

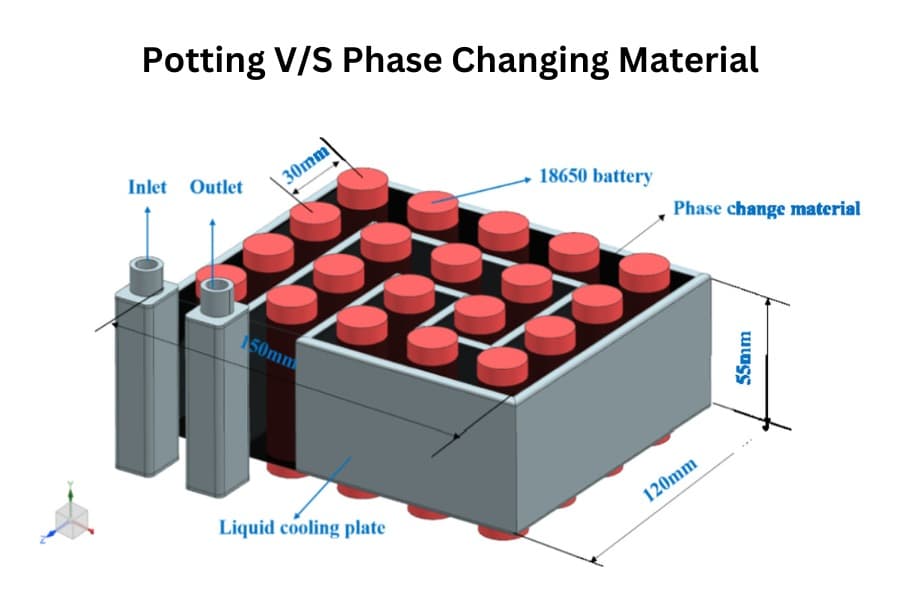

3. Phase Change Material (PCM) Integration

PCM-based cooling systems are gaining attention for their ability to absorb and release thermal energy effectively. Incorporating PCMs into lithium battery cooling technologies has shown significant improvements in temperature control and energy efficiency.

4. Immersion Cooling for High Efficiency

Immersion cooling involves submerging battery cells in dielectric fluids, which provide excellent heat dissipation. This method ensures consistent performance and prevents thermal runaway, reinforcing the reliability of lithium battery cooling technologies in demanding scenarios.

5. Hybrid Cooling Systems: The Future of Thermal Management

Hybrid systems that integrate air, liquid, PCM, and thermoelectric cooling offer the best of all methods. These systems represent the next generation of lithium battery cooling technologies, achieving superior thermal management across various applications.

Lithium battery cooling technologies are revolutionizing the energy storage industry. From advanced air-cooling systems to innovative hybrid approaches, these solutions are integral to meeting the growing demands for high-performance, safe, and efficient batteries. As research and development continue, the future of lithium-ion batteries will rely heavily on these cutting-edge cooling technologies.

How Battery Swapping Could Transform the EV Ecosystem in India

India is seeing rapid growth in its population and cities. This growth is driving big changes in how people travel. The country is pushing for electric vehicles (EVs) to reduce air pollution, cut down fuel imports, and improve sustainability. Among the many solutions being explored, battery swapping stands out as a game-changer for making EVs more practical and affordable.

The Case for Battery Swapping

Battery swapping involves replacing a discharged battery with a fully charged one at specialized swapping stations, bypassing the time-consuming charging process. This concept has garnered attention for its potential to address several critical challenges in India’s EV adoption journey.

- Reduction in Upfront Costs: One of the primary barriers to EV adoption in India is the high upfront cost, largely driven by expensive lithium-ion batteries. Battery swapping decouples battery ownership from the vehicle, allowing consumers to purchase EVs without the hefty cost of a battery. Instead, users can pay for batteries on a subscription basis, significantly lowering the entry price of EVs.

- Eliminating Range Anxiety: Range anxiety, or the fear of running out of battery charge mid-journey, is a significant deterrent for potential EV buyers. Battery swapping offers a quick and convenient solution, as swapping stations can provide a fully charged battery in a matter of minutes, similar to refueling at a petrol pump.

- Optimizing Charging Infrastructure: Setting up extensive charging networks across a vast country like India is a daunting and expensive task. Battery swapping requires fewer charging stations since batteries can be charged centrally and distributed to swapping locations. This reduces infrastructure costs and energy demand spikes.

- Supporting Commercial EVs: Commercial vehicles such as e-rickshaws, delivery vans, and two-wheelers form a significant portion of India’s transportation sector. These vehicles often operate on tight schedules and cannot afford prolonged charging downtimes. Battery swapping ensures minimal downtime, improving efficiency and productivity.

Challenges and Solutions

While the benefits of battery swapping are clear, the concept is not without challenges:

- Standardization of Batteries: A lack of standardization across EV manufacturers can hinder the interoperability of batteries. Addressing this requires industry-wide collaboration and regulatory intervention to establish common standards.

- Battery Management and Quality Control: Ensuring that swapped batteries are of high quality and not degraded over time is crucial. Implementing rigorous testing and certification protocols can mitigate risks associated with battery health and safety.

- Economic Viability: Battery swapping stations require significant investment in infrastructure and inventory. Partnerships between government, private companies, and startups can help share the financial burden and scale operations efficiently.

- Technology Adaptation: Integrating IoT and blockchain technologies can enhance the battery swapping ecosystem by enabling real-time tracking, usage monitoring, and seamless transactions for consumers.

Government Initiatives and Industry Efforts

The Indian government has recognized the potential of battery swapping in accelerating EV adoption. Initiatives such as the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) II scheme emphasize support for innovative solutions like battery swapping. Additionally, the government is exploring incentives for swapping station operators and measures to promote battery standardization.

Private players, too, are stepping up. Companies like Sun Mobility, Lithion Power, and Battery Smart are piloting battery swapping networks, particularly for two- and three-wheelers. These efforts, coupled with increasing consumer awareness, are laying the groundwork for a robust battery-swapping ecosystem.

Transforming India’s EV Landscape

Battery swapping is more than a technical innovation; it is a systemic change that could redefine the economics and convenience of EV ownership in India. By addressing key consumer concerns and infrastructure challenges, battery swapping has the potential to accelerate the country’s transition to sustainable mobility.

As India gears up for widespread EV adoption, battery swapping could emerge as a critical enabler, especially for urban and semi-urban regions. If scaled effectively, this solution could not only enhance EV penetration but also create a ripple effect on employment, energy security, and environmental sustainability.

Battery swapping is not just a concept; it is a catalyst for India’s electric revolution—a revolution that promises to reshape transportation, reduce emissions, and build a cleaner, greener future.

BIS Standards for Lithium Batteries in India

Lithium batteries are at the heart of modern technology, powering everything from smartphones to electric vehicles (EVs). As India advances toward electric mobility and renewable energy goals, ensuring the safety, reliability, and performance of lithium batteries has become crucial. The Bureau of Indian Standards (BIS) has stepped in to address these needs with a comprehensive framework of standards tailored for lithium batteries. These standards aim to prevent risks like overheating and explosions, establish uniform benchmarks for manufacturers, and boost consumer confidence in the rapidly expanding market for lithium batteries in India.

What Are BIS Standards?

The Bureau of Indian Standards (BIS) is the national standard body of India responsible for developing and enforcing safety and quality standards across industries. BIS standards for lithium batteries ensure that these energy storage devices meet stringent safety, performance, and reliability benchmarks. They also align with international norms to support India’s integration into global markets.

Key BIS Standards for Lithium Batteries

IS 16046-1 and IS 16046-2: These standards are based on the international IEC 62133 framework. They ensure the safety and reliability of lithium-ion and lithium-polymer batteries used in portable devices like smartphones, laptops, and power banks.

IS 16893: This standard is designed for large-format batteries, such as those used in electric vehicles and renewable energy storage systems. It specifies requirements for safe design, assembly, and testing of lithium-ion battery packs.

IS 17092: Focusing on solar energy applications, this standard lays out safety and testing criteria for cells and batteries used in renewable energy storage solutions.

Performance Testing Standards: To address the Indian climate, BIS mandates testing for performance under extreme conditions, such as charge/discharge cycles, thermal stress, and short circuits, ensuring durability and reliability.

Why BIS Standards Are Important

Ensuring Safety: Lithium batteries can pose risks such as overheating, fire, and explosions if poorly designed or manufactured. BIS standards mitigate these risks through strict testing and quality assurance protocols.

Boosting Consumer Trust: When manufacturers adhere to BIS standards, consumers are assured of the safety and reliability of the batteries they use, fostering trust in both products and brands.

Promoting “Make in India”: By providing a clear regulatory framework, BIS standards encourage domestic production, reducing reliance on imports and supporting India’s vision of becoming a global manufacturing hub.

Global Competitiveness: Aligning with international standards like IEC 62133 and ISO 12405 ensures that Indian-made lithium batteries can compete in global markets, opening up export opportunities.

Future of Lithium Batteries in India

BIS standards are pivotal for ensuring the safe and sustainable adoption of lithium batteries in India. To streamline implementation, the government and industry stakeholders should expand testing infrastructure, offer incentives for compliance, and raise awareness about the importance of certified products. These efforts will not only address safety concerns but also accelerate India’s transition to clean energy and electric mobility.

Moving ahead

BIS standards for lithium batteries in India set a high benchmark for safety, performance, and reliability. They play a vital role in protecting consumers, supporting domestic manufacturing, and aligning Indian products with global standards. As demand for lithium batteries grows, these standards will be instrumental in shaping a safe, sustainable, and competitive future for the industry.

How the Government of India Is Supporting Indian Battery Manufacturers

The Indian government is making significant strides to support domestic battery manufacturing, recognizing its pivotal role in the nation’s transition to green energy, self-reliance, and economic growth. In this blog, we delve into the initiatives, policies, and frameworks that are empowering Indian battery manufacturers and boosting their global competitiveness.

India is embarking on a transformative journey toward sustainable energy, where battery manufacturing is a cornerstone. Batteries power electric vehicles (EVs), renewable energy storage solutions, and various consumer electronics. Aware of its importance, the Government of India has introduced a series of initiatives to foster the growth of domestic manufacturers and position India as a global leader in this sector.

Importance of Battery Manufacturing

Role in Energy Transition

Batteries enable efficient storage and utilization of renewable energy sources like solar and wind, reducing India’s dependence on fossil fuels. By promoting indigenous battery manufacturing, the government aims to build a robust, sustainable energy infrastructure.

Support for EVs

Electric vehicles rely on advanced battery systems. To reduce carbon emissions and drive EV adoption, the government is prioritizing the development of high-performance, cost-effective batteries.

Government Initiatives Supporting Battery Manufacturing

The Make in India Initiative is a cornerstone of the Indian government’s efforts to promote domestic manufacturing, including the battery industry. This campaign aims to reduce reliance on imports by encouraging Indian manufacturers to produce high-quality batteries locally, thereby fostering self-reliance. A significant focus is placed on innovation, with an emphasis on research and development to create cost-effective and sustainable battery solutions that cater to both domestic and global markets.

Complementing this is the Production Linked Incentive (PLI) Scheme, a transformative policy for the battery manufacturing sector. Its primary objective is to establish a robust manufacturing base for advanced batteries, prioritizing technological advancements and enhancing market competitiveness. With a substantial budget allocation of ₹18,100 crore, the scheme offers financial incentives tied to production milestones, enabling manufacturers to achieve economies of scale and boosting overall industry growth.

The Battery Swapping Policy adds another layer of innovation by addressing cost and convenience challenges for EV users. This policy emphasizes the standardization and interoperability of battery swapping systems, creating a seamless experience for consumers while opening up new opportunities for manufacturers. By encouraging the production of swappable and efficient battery systems, it reduces the financial burden of battery ownership and promotes wider EV adoption.

Lastly, the government’s Focus on EV Ecosystem is underscored by the FAME India Scheme (Faster Adoption and Manufacturing of Hybrid and Electric Vehicles). This initiative has played a pivotal role in accelerating the adoption of EVs in India by offering incentives that create consistent demand for high-quality batteries. Together, these initiatives highlight the government’s comprehensive strategy to support and advance the Indian battery manufacturing industry, driving innovation, sustainability, and economic growth.

Supporting Innovation and Infrastructure

The Indian government is actively supporting research and development in battery technology by providing grants and fostering collaborations between academic institutions and industries. This approach is helping to advance cutting-edge technologies, including lithium-ion and solid-state batteries, which are pivotal for the country’s energy transition. To further boost the sector, the government has implemented significant taxation and duty benefits. For instance, the Goods and Services Tax (GST) rate on EVs and batteries has been reduced to 5%, making them more affordable for manufacturers and consumers alike. Additionally, temporary import duty exemptions on critical raw materials aim to encourage the localization of battery production, reducing dependency on imports.

In terms of infrastructure, specialized battery parks are being established to streamline manufacturing processes and attract investments. These parks offer an integrated environment for battery production, fostering efficiency and innovation. Moreover, the government is upgrading logistics networks to ensure the efficient transportation of raw materials and finished products, thus enhancing the overall supply chain and boosting the industry’s growth potential.

Investment and Skill Development

The Indian government is actively fostering investment and skill development in the battery manufacturing sector to strengthen its foundation and ensure long-term growth. Substantial government subsidies are provided to both startups and established firms, encouraging them to venture into battery production and innovation. Additionally, eased regulatory norms are attracting significant foreign direct investment (FDI), enabling global players to collaborate with domestic manufacturers and bolster India’s manufacturing capabilities.

On the workforce front, the government is prioritizing skill development initiatives to meet the industry’s growing demands. Specialized training programs are being designed to create a skilled workforce adept at handling the latest battery manufacturing technologies. Furthermore, there is a strong emphasis on workforce upskilling, ensuring employees stay updated with technological advancements and can contribute effectively to the sector’s progress. Together, these efforts are creating a robust ecosystem that supports both industrial and human resource development in the battery manufacturing industry.

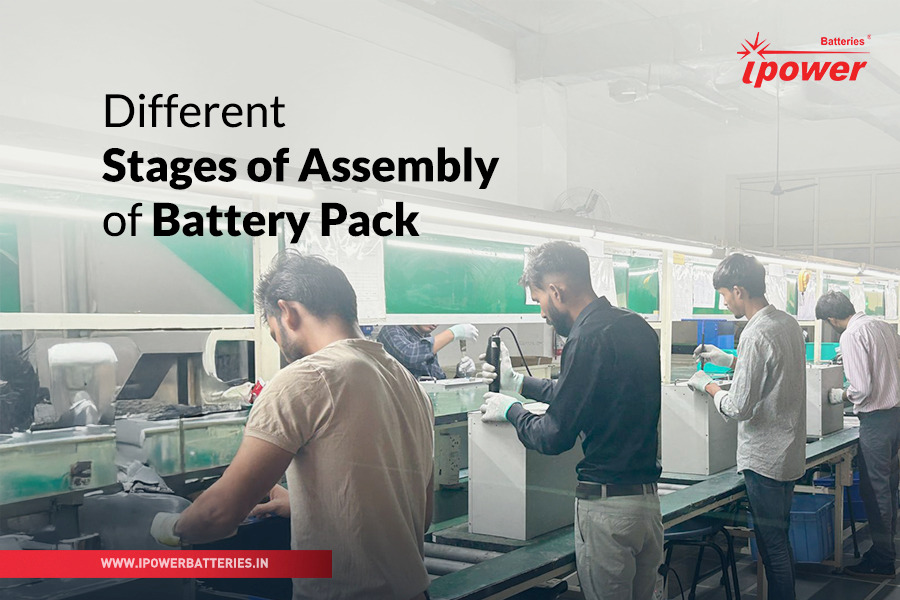

Different Stages of Battery Pack Assembly at iPower Batteries

Battery packs are the backbone of modern energy storage solutions, powering everything from electric vehicles to renewable energy systems. At iPower Batteries, a leading lithium battery pack manufacturer in India, we take pride in our comprehensive, precision-driven battery pack assembly process that ensures reliable and long-lasting battery packs. In this article, we outline the different stages of assembly that we use to produce high-quality lithium battery packs, focusing on safety, efficiency, and the advanced techniques we employ at each step.

Cell Selection and Grading in Battery Pack Assembly

The foundation of a reliable battery pack begins with selecting the right cells. At iPower Batteries, we source high-quality lithium-ion cells from reputable manufacturers and then perform an extensive grading process. This step ensures that all cells meet our strict quality standards for performance, capacity, and lifespan.

- Quality Checks: Each cell undergoes voltage, capacity, and internal resistance testing.

- Sorting and Pairing: Cells are grouped based on their performance characteristics to ensure uniform energy output across the pack.

This meticulous cell grading process is crucial for creating battery pack assemblies with optimal balance, extended lifespan, and improved thermal management.

Cell Arrangements and Mechanical Design

Once the cells are selected and graded, they are arranged into specific configurations based on the application requirements. Our engineering team at iPower Batteries designs custom configurations to meet the voltage and capacity demands of our customers.

- Series and Parallel Arrangements: Cells are connected in series to increase voltage or in parallel to boost capacity, as per the specifications.

- Structural Support: We employ high-strength brackets and holders to secure cells in place and protect them from mechanical stress.

Our mechanical design ensures that cells remain stable and secure throughout the battery pack assembly lifecycle, even in challenging operating conditions.

Spot Welding and Electrical Connections in Battery Pack Assembly

The cells are connected through a process known as spot welding, which uses controlled electric pulses to fuse cells to the battery terminals.

- High Precision Spot Welding: At iPower Batteries, we use advanced spot-welding machines to create durable connections that withstand vibrations and temperature variations.

- Inter-cell Connectors: High-quality nickel strips or copper connectors are used for efficient current flow between cells.

Proper welding techniques and materials are essential in battery pack assembly to minimize electrical resistance, which in turn reduces heat generation and increases battery efficiency.

Incorporating Battery Management System (BMS)

The Battery Management System (BMS) is an integral component in any lithium battery pack. The BMS monitors and controls the battery’s charging and discharging, ensuring safety and efficiency.

- Balancing Cells: Our BMS technology balances the charge among cells to prevent overcharging or deep discharging.

- Temperature Management: iPower’s BMS systems have temperature sensors that monitor cell temperatures, activating cooling mechanisms if necessary.

- Protective Features: Our BMS protects against overcurrent, short circuits, and voltage imbalances, extending battery life and enhancing user safety.

By incorporating a reliable BMS, we ensure that every iPower battery pack assembly operates safely, even under heavy load conditions.

Thermal Management Solutions for Battery Pack Assembly

Lithium battery packs generate heat during use, and excessive heat can impact performance and safety. At iPower Batteries, we use a combination of thermal management solutions to mitigate these risks.

- Thermal Pads and Insulators: We place thermal pads between cells to dissipate heat evenly.

- Heat-Shrinking Wraps: High-quality wraps are used to shield the pack from external temperatures and environmental contaminants.

Effective thermal management helps prevent thermal runaway—a key safety feature in every battery pack assembly we produce.

Enclosure and Packaging

Once the internal assembly is complete, the cells and components are securely housed in a durable enclosure. This stage involves selecting materials that provide protection from external shocks, moisture, and dust.

- Weatherproof Casings: Our battery packs are encased in waterproof and shock-resistant materials, ideal for both indoor and outdoor applications.

- Labeling and Compliance Marking: Each pack is labeled according to regulatory standards, providing clear information on specifications, safety warnings, and recycling information.

The enclosure and packaging are essential to maintaining the battery’s integrity and providing additional safety layers in the battery pack assembly.

Final Testing and Quality Assurance

Before a battery pack is approved for delivery, it undergoes rigorous testing to ensure it meets all performance and safety standards. Our quality control team at iPower Batteries conducts comprehensive testing protocols, including:

- Load Testing: Battery packs are tested under simulated real-life loads to verify capacity and endurance.

- Environmental Stress Testing: Packs are exposed to varying temperatures and humidity to assess durability under different conditions.

- Charge/Discharge Cycles: We cycle test every battery pack to guarantee consistent performance over time.

By implementing stringent quality checks, we ensure that every battery pack assembly we produce is safe, efficient, and reliable, ready to support demanding applications.

The Emerging Energy Storage Systems (ESS) Market in Tier 2 and Tier 3 Cities in India

At Ipower, we believe that India’s energy landscape is changing rapidly, especially with the growing need for clean, reliable energy and the country’s focus on renewable power. While big cities have been quick to adopt renewable energy and energy storage systems (ESS), we are seeing a lot of potential in smaller cities—Tier 2 and Tier 3 cities—which are playing a more important role in India’s shift towards clean energy. The demand for dependable and affordable energy storage is increasing, and this opens up great opportunities for ESS providers.

Why Focus on Tier 2 and Tier 3 Cities?

Increasing Energy Needs

Smaller cities in India are growing, leading to higher energy demand due to more urbanization, industrial activities, and business growth. Though these cities are not as crowded as the bigger ones, their power needs are rising, and the existing infrastructure struggles to keep up. Unreliable electricity and power outages are common, making efficient energy storage systems crucial to filling the gap.

Push for Renewable Energy

The government’s push for renewable energy isn’t just focused on big cities. In Tier 2 and Tier 3 cities, people are becoming more aware of how important it is to combine renewable energy sources, like solar and wind, with energy storage. With lots of available land and plenty of sunlight, these cities are great places for solar power projects, which is increasing the demand for ESS.

What’s Driving the Demand for ESS in Smaller Cities?

- Electrification and Grid Upgrades: While access to electricity has improved across India, smaller cities still face issues like inconsistent power supply and voltage fluctuations. Energy storage can help improve grid reliability, providing backup power to industries, businesses, and homes.

- Growth of Small Industries: Many small and medium-sized businesses operate in Tier 2 and Tier 3 cities. These businesses are vital to India’s economy but often struggle with unreliable power. Energy storage solutions, especially battery-based ones, can help them by offering stable backup power, which cuts their need for diesel generators and lowers costs.

- Increasing Use of Solar Power: Rooftop solar systems are becoming more popular in these cities, thanks to government incentives and falling prices for solar panels. But solar energy is only available when the sun is shining, so energy storage is essential to store extra energy and provide steady power when it’s needed.

- Rising Residential Demand: As living standards improve and incomes rise in smaller cities, more people want uninterrupted power in their homes. By pairing energy storage systems with solar installations, households can have reliable power even during outages.

Government Support for ESS

The Indian government understands the importance of energy storage in achieving its renewable energy goals and has introduced several initiatives to support ESS:

National Energy Storage Mission (NESM): This program aims to create a strong energy storage market in India, focusing on both large-scale and smaller, localized storage solutions. Smaller cities will benefit from this push as the government encourages ESS adoption across the country.

Incentives for Rooftop Solar with Storage: The government offers subsidies for rooftop solar systems that include energy storage, making these systems more affordable for homes and businesses in smaller cities.

Challenges in the ESS Market for Smaller Cities

High Initial Costs: While costs are coming down, energy storage systems still require a large upfront investment, which might be difficult for small businesses and households in Tier 2 and Tier 3 cities. But with financing options, government subsidies, and models like ESS-as-a-service, these barriers can be reduced.

Lack of Awareness: Many people in smaller cities aren’t fully aware of how energy storage systems can benefit them in the long run. More efforts are needed to educate both consumers and businesses on the advantages of ESS.

Supply Chain and Infrastructure Issues: The availability of skilled workers and access to advanced technology in smaller cities can be limited. Building a strong supply chain and investing in training will be key to overcoming these obstacles.

The energy storage market in Tier 2 and Tier 3 cities is still in its early stages, but the potential is huge. As these cities continue to grow, the need for affordable, reliable, and clean energy will increase. At Ipower, we see a big opportunity to provide scalable, cost-effective, and flexible energy storage solutions tailored to meet the needs of these smaller cities. For India to meet its renewable energy targets and build a strong energy infrastructure, these cities must be at the center of the transition, and energy storage systems will play a crucial role in making this happen.

Emerging Trends in EV Battery Technology in India

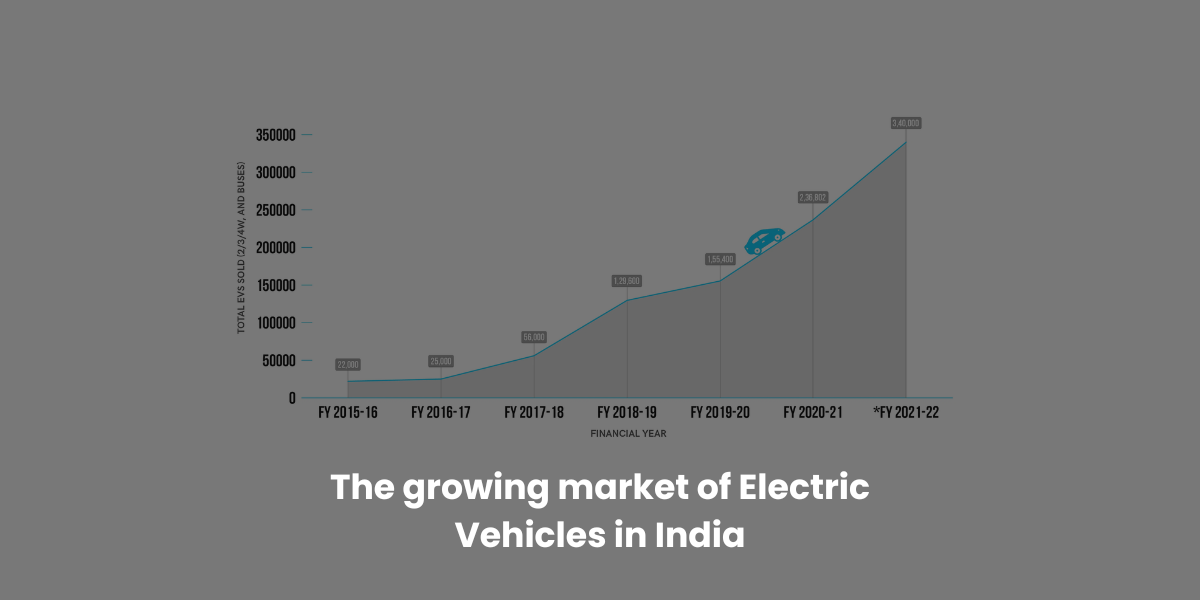

India’s electric vehicle (EV) market is on a remarkable upward trajectory, fueled by the growing demand for eco-friendly transportation solutions. This surge has accelerated advancements in EV battery technology, which is essential for supporting the nation’s ambitious electrification goals.

Below, we explore some of the key emerging trends in EV battery technology in India, supported by the latest industry insights:

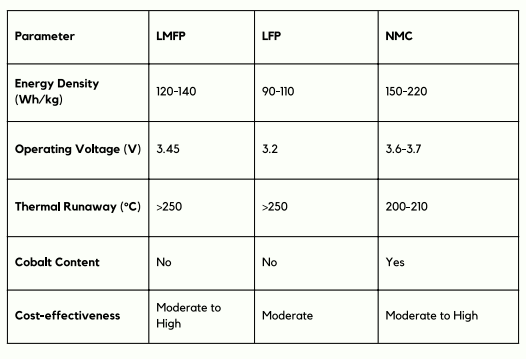

Transition to Advanced Battery Chemistries

India is seeing a significant shift in battery chemistries, with a growing preference for Lithium Iron Phosphate (LFP) batteries. This shift is driven by the safety features of LFP batteries and their relative insulation from geopolitical risks, such as those associated with the supply of raw materials.

Unlike other chemistries, LFP batteries do not rely heavily on cobalt and nickel, which are often sourced from regions with complex geopolitical landscapes. This makes LFP batteries a more secure and stable option for Indian manufacturers.

As a result, the market is increasingly moving away from higher-energy-density chemistries like Nickel Cobalt Manganese (NCM) in favor of LFP, which offers a balance of safety, cost-effectiveness, and supply chain stability, making it a preferred choice for a wide range of EV applications in India.

Rise of Solid-State Batteries and Rapid Charging Solutions

Solid-state batteries, which offer higher energy density, improved safety, and faster charging times, are gaining attention in India. Although still in the development phase, these batteries represent the next frontier in EV technology.

Globally, solid-state batteries are expected to achieve commercial viability by 2030, and Indian companies are increasingly exploring this technology as part of their long-term strategies.

These batteries could potentially reduce charging times to under 30 minutes, making EVs more convenient for daily use.

Boost in Domestic Manufacturing Capabilities

India is gradually reducing its dependence on imported lithium-ion cells, thanks to increased investments in local battery manufacturing. The Indian government has introduced initiatives like the Production-Linked Incentive (PLI) scheme for advanced chemistry cells and the Faster Adoption and Manufacturing of Electric Vehicles (FAME) scheme to support the establishment of local gigafactories.

By 2030, it is anticipated that 13% of India’s EV battery demand will be met through domestic production, a significant increase from current levels. For instance, Ola Electric’s gigafactory in Chennai is already producing cylindrical cells for electric two-wheelers.

Focus on Recycling and Sustainability

As the use of lithium-ion batteries increases, recycling has emerged as a crucial area of focus. Indian companies are adopting advanced recycling processes, such as hydrometallurgy and solvo-metallurgy, to recover key materials like lithium, cobalt, and nickel from used batteries. This not only reduces reliance on raw material imports but also aligns with India’s broader sustainability goals.

The European Union aims to recover 50% of lithium from old batteries by 2027, a benchmark that Indian companies are also working towards as they expand their recycling efforts.

Expansion of Battery-as-a-Service (BaaS) Model

The Battery-as-a-Service (BaaS) model is gaining traction in India, particularly among commercial fleet operators. BaaS allows users to lease batteries separately from vehicles, facilitating quicker battery swaps and lowering the upfront cost of EVs.

This model is particularly appealing in the price-sensitive Indian market, where affordability is a significant barrier to widespread EV adoption. The BaaS model is expected to play a crucial role in increasing EV adoption rates across the country.

Growth in the Two-Wheeler and Three-Wheeler Segments

The two-wheeler and three-wheeler segments are at the forefront of the EV revolution in India, accounting for over 85% of all EV sales. In the past year alone, EV sales in India reached 1.4 million units, with two-wheelers comprising the majority of these sales. These segments are driving innovation in battery technology, with a focus on developing compact, efficient, and cost-effective solutions that cater to the unique needs of the Indian market. Additionally, battery management systems (BMS) are playing a vital role in optimizing the performance and lifespan of batteries in these vehicles.

Towards the end…

India’s EV battery technology landscape is evolving rapidly, driven by a combination of government policies, market demand, and technological innovation. As the country advances towards its electrification goals, improvements in battery technology will be crucial in making EVs a mainstream option for consumers. The focus on developing advanced chemistries, boosting domestic manufacturing, and enhancing sustainability practices will shape the future of the EV industry in India.

These trends underscore the dynamic nature of India’s EV industry, positioning the country as a significant player in the global shift towards electric mobility.

Role of Battery Recycling and Repurposing in the Indian Economy by 2030

The transition to a sustainable energy future is a priority for India, driven by the need to reduce carbon emissions and enhance energy security. Central to this transition is the widespread adoption of renewable energy sources and electric vehicles (EVs), both of which rely heavily on batteries, particularly lithium-ion batteries. As the usage of these batteries escalates, the challenges associated with their end-of-life management become increasingly significant. Battery recycling and repurposing offer a viable solution, presenting not only environmental benefits but also substantial economic opportunities for India by 2030.

Current Scenario of Battery Usage in India

Growth in Renewable Energy and EV Adoption:

India’s renewable energy capacity has been expanding at an unprecedented rate, with the government targeting 175 GW of renewable energy by 2022 and 450 GW by 2030. This growth is complemented by the push towards electric mobility, supported by initiatives such as the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme. The proliferation of solar and wind energy projects, along with an increasing number of EVs on the road, has led to a surge in the demand for energy storage solutions.

Challenges of Battery Waste Management:

The surge in battery usage brings about significant challenges in waste management. Lithium-ion batteries, which are commonly used in both renewable energy storage and EVs, contain hazardous materials such as lithium, cobalt, and nickel. Improper disposal can lead to environmental contamination, posing risks to soil and water quality, and subsequently human health. Furthermore, the extraction of raw materials for battery production is resource-intensive and environmentally detrimental, necessitating sustainable end-of-life solutions for these batteries.

Benefits of Battery Recycling

Environmental Protection:

Battery recycling mitigates environmental pollution by preventing the release of toxic substances into the environment. The recycling process involves the recovery of valuable metals and materials, which are then reused in the production of new batteries. This reduces the demand for virgin raw materials and the associated environmental impacts of mining and processing.

Conservation of Natural Resources:

Recycling batteries enables the recovery of critical materials such as lithium, cobalt, nickel, and manganese. These materials are finite and their extraction is often linked to significant environmental degradation. By recycling, the need for new mining operations is diminished, conserving natural resources and reducing the ecological footprint of battery production.

Economic Advantages:

Recycling batteries presents considerable economic benefits. The recovery of valuable metals reduces the reliance on imported raw materials, which are often subject to price volatility. Additionally, the recycling industry can generate employment opportunities, contributing to economic growth. The establishment of a robust battery recycling infrastructure can also foster technological innovation and position India as a leader in sustainable battery management.

Role of Battery Repurposing

Extending Battery Lifespan:

Repurposing involves reusing batteries that are no longer suitable for their original application but still retain a significant portion of their capacity. For instance, batteries from EVs can be repurposed for less demanding applications such as stationary energy storage systems. This approach extends the useful life of batteries, delaying their entry into the waste stream.

Enhancing Renewable Energy Storage:

Repurposed batteries can play a crucial role in supporting renewable energy systems. They can be integrated into energy storage solutions to store excess power generated from renewable sources like solar and wind. This stored energy can then be used during periods of low generation, ensuring a stable and reliable power supply. Repurposing batteries in this manner not only supports the integration of renewable energy into the grid but also enhances energy resilience.

Economic Impact of Repurposing:

The market for second-life batteries is emerging as a cost-effective alternative for energy storage solutions. By repurposing batteries, the initial investment costs for energy storage can be reduced, making renewable energy systems more economically viable. This can accelerate the adoption of renewable energy technologies, driving economic growth and contributing to energy security.

Government Initiatives and Policies

National Battery Policy:

The Indian government is actively working towards establishing a comprehensive battery policy to address the challenges and opportunities associated with the battery lifecycle. This policy aims to promote sustainable practices in battery production, usage, and disposal. Key components of the policy are expected to include guidelines for recycling and repurposing, standards for battery design to facilitate easier recycling, and incentives for the adoption of sustainable practices.

Incentives and Support for Recycling and Repurposing:

To encourage the development of a battery recycling and repurposing industry, the government is offering various incentives. These include tax benefits, subsidies for setting up recycling plants, and grants for research and development in advanced recycling technologies. Additionally, regulatory frameworks are being established to ensure safe and efficient recycling practices, fostering investor confidence in the sector.

Future Prospects

Technological Advancements:

The future of battery recycling and repurposing is closely linked to technological advancements. Innovations in recycling technologies are expected to enhance the efficiency and cost-effectiveness of the process. For example, hydrometallurgical and direct recycling methods are being developed to improve material recovery rates and reduce environmental impact. Similarly, advancements in battery design, such as modular and easy-to-disassemble batteries, can facilitate more efficient recycling and repurposing.

Market Expansion:

The market for recycled and repurposed batteries is poised for significant growth. As awareness of the environmental and economic benefits of recycling and repurposing increases, and as regulatory frameworks become more supportive, the demand for these solutions is expected to rise. By 2030, India could become a global hub for battery recycling and repurposing, leveraging its large domestic market and technological capabilities.

Moving Forward

Battery recycling and repurposing are set to play a pivotal role in the Indian economy by 2030. These practices offer a sustainable solution to the challenges posed by the increasing use of batteries, providing environmental protection, resource conservation, and economic benefits. With supportive government policies, technological advancements, and growing market demand, India has the potential to establish a robust and innovative battery recycling and repurposing industry, contributing to a sustainable and prosperous future.

The Evolution of Solid-State Batteries: What’s Next?

The landscape of energy storage is experiencing a transformative shift with the advent of solid-state batteries (SSBs). As the demand for higher efficiency, safety, and energy density in batteries grows, SSBs are emerging as a promising solution. This blog explores the evolution of solid-state batteries, their current state, and what the future holds for this groundbreaking technology.

The Journey So Far: A Brief History of Solid-State Batteries

Solid-state batteries have been a topic of research since the mid-20th century. However, it wasn’t until the late 20th and early 21st centuries that significant advancements were made. Traditional lithium-ion batteries, which use liquid electrolytes, have dominated the market for decades. Despite their widespread use, they come with several drawbacks, including safety risks like leakage and flammability, limited energy density, and relatively short lifespan.

The concept of SSBs involves replacing the liquid electrolyte with a solid electrolyte. This fundamental change offers several potential benefits:

Safety: Solid electrolytes are non-flammable, reducing the risk of battery fires.

Energy Density: Higher energy density translates to longer-lasting batteries.

Lifespan: Reduced degradation over time means a longer lifespan for the battery.

Current State of Solid-State Battery Technology

The past decade has seen significant strides in the development of SSBs. Companies like Toyota, QuantumScape, and Solid Power have made headlines with their breakthroughs. For instance, QuantumScape announced in 2020 that it had developed a solid-state battery capable of reaching an 80% charge in just 15 minutes, with a lifespan of over 800 cycles.

Despite these advancements, several challenges remain:

Material Compatibility: Finding suitable solid electrolytes that can operate efficiently at room temperature.

Manufacturing: Developing scalable and cost-effective manufacturing processes.

Performance Consistency: Ensuring the reliability and performance of SSBs in real-world conditions.

Notable Developments

Lithium Metal Anodes: Replacing traditional graphite anodes with lithium metal can significantly increase energy density. However, this also introduces challenges related to dendrite formation, which can short-circuit the battery.

Ceramic Electrolytes: Materials like garnet and sulfides are being explored for their high ionic conductivity and stability.

Polymer Electrolytes: Offering flexibility and ease of manufacturing, polymer electrolytes are another area of active research.

The Road Ahead: What’s Next for Solid-State Batteries?

The future of solid-state batteries looks promising, with several key trends and potential breakthroughs on the horizon:

1. Commercialization and Mass Production

One of the biggest hurdles for SSBs is transitioning from the lab to the market. As companies ramp up their efforts, we can expect to see the first commercial solid-state batteries within the next few years. This transition will be crucial in addressing issues related to cost, scalability, and performance consistency.

2. Automotive Applications

The automotive industry stands to benefit significantly from SSB technology. Electric vehicles (EVs) equipped with solid-state batteries could offer longer ranges, shorter charging times, and improved safety. Toyota plans to showcase its solid-state battery-powered vehicle by the mid-2020s, which could be a game-changer for the EV market.

3. Integration with Renewable Energy

Solid-state batteries could play a vital role in renewable energy storage solutions. Their high energy density and safety features make them ideal for integrating with solar and wind power systems, helping to stabilize the grid and provide reliable power storage.

4. Innovative Materials and Designs

Research into new materials and battery designs will continue to drive the evolution of SSBs. Innovations such as hybrid solid-liquid electrolytes, novel solid electrolytes with higher ionic conductivity, and 3D battery architectures could further enhance performance and durability.

5. Environmental Impact and Sustainability

As the world moves towards a more sustainable future, the environmental impact of battery production and disposal will be a critical consideration. Solid-state batteries, with their potential for longer lifespans and safer chemistries, could offer more environmentally friendly options compared to conventional batteries.

Conclusion

The evolution of solid-state batteries marks a significant milestone in the quest for better energy storage solutions. While challenges remain, the potential benefits of SSBs in terms of safety, energy density, and longevity are driving rapid advancements in the field. As research and development continue to push the boundaries, the future of solid-state batteries looks brighter than ever, promising to revolutionize not only the energy storage industry but also the broader landscape of renewable energy and electric mobility.

In summary, the journey of solid-state batteries is one of innovation and potential. With continued investment and research, we are on the cusp of a new era in energy storage that could redefine how we power our world. So, keep an eye on this space – the next big breakthrough in battery technology might be just around the corner.

Rise of EV Charging Stations in India: Adding Value to Real Estate Economics

India is witnessing a significant surge in the adoption of electric vehicles (EVs), driven by the government’s push for reducing carbon emissions and promoting sustainable mobility. As of February 2024, the country has 12,146 operational public EV charging stations, a substantial increase from the previous year. This rise is reshaping the landscape of real estate economics, offering new value propositions for properties equipped with EV charging facilities.

Government Initiatives and Policy Support

The Indian government has been proactive in fostering the growth of EV infrastructure through various policies and initiatives. The FAME II (Faster Adoption and Manufacturing of Hybrid and Electric Vehicles) scheme, extended until March 31, 2024, has been a significant driver, with a budget allocation of ₹10,000 crore. This scheme aims to install thousands of new charging stations across the country, including strategic locations like highways and major urban centers.

Impact on Real Estate Economics

The integration of EV charging stations into real estate properties is transforming the sector, offering several economic benefits:

1. Increased Property Value and Demand

Properties with EV charging facilities are becoming highly sought after. Homebuyers and tenants are increasingly viewing EV charging stations as essential amenities. This trend has led to a rise in property values for buildings equipped with charging infrastructure. According to recent reports, properties with EV charging stations can command a premium of 2-5%.

2. Enhanced Tenant Retention and Attraction

For commercial real estate, providing EV charging facilities can be a significant differentiator. Businesses aiming to attract and retain environmentally conscious tenants find EV charging stations a valuable addition. This can lead to longer lease terms and lower vacancy rates, as tenants appreciate the convenience and sustainability benefits.

3. Revenue Generation Opportunities

Property owners can leverage EV charging stations to create additional revenue streams. Charging fees, subscription models, and partnerships with charging network operators can generate steady income. Moreover, advertising opportunities on charging stations can further boost revenue.

4. Positive Environmental Impact and Corporate Image

Installing EV charging stations aligns with corporate sustainability goals, enhancing the green credentials of businesses and properties. This positive environmental impact can attract eco-conscious customers and improve the public image of companies, contributing to business growth and brand loyalty.

5. Future-Proofing Real Estate Investments

As the adoption of EVs continues to rise, properties without charging infrastructure may face obsolescence. Investing in EV charging stations now ensures that properties remain relevant and competitive in the future, safeguarding their market value.

Challenges and Considerations

Despite the benefits, there are challenges in the widespread adoption of EV charging infrastructure. The initial cost of installation, grid capacity issues, and the need for standardized charging protocols are significant hurdles. Collaboration between government bodies, utility companies, and private players is essential to overcome these challenges and create a robust charging network.

Conclusion

The rise of EV charging stations in India is not only facilitating the transition to electric mobility but also redefining the economics of the real estate sector. By enhancing property value, attracting tenants, generating revenue, and aligning with sustainability goals, EV charging stations are adding significant value to real estate investments. As India continues to embrace sustainable transportation, the integration of EV charging infrastructure will play a crucial role in its success, offering substantial benefits to the real estate sector and beyond.

How to Keep Your Electric Scooter Safe in This Scorching Summer

As India faces unprecedented heat waves, with temperatures soaring up to 50 degrees Celsius, ensuring the safety of your electric scooter becomes paramount. This summer, cities like Delhi, Jaipur, and Ahmedabad have recorded alarmingly high temperatures, making it critical for electric vehicle (EV) enthusiasts to take extra precautions.

For electric scooters powered by lithium-ion batteries, the extreme heat poses unique challenges that can impact both safety and performance.

Here’s how you can keep your electric scooter safe during this intense summer, brought to you by Ipower Batteries, a leading manufacturer of lithium battery packs for 2W and 3W in India.

Understanding the Impact of Heat on Lithium-Ion Batteries

Lithium-ion batteries, while efficient and reliable, are sensitive to temperature extremes. High temperatures can:

Accelerate Degradation: Heat speeds up the chemical reactions inside the battery, leading to faster degradation and reduced lifespan. In cities where temperatures regularly exceed 40 degrees Celsius, this can be a significant concern.

Cause Thermal Runaway: Excessive heat can lead to a dangerous situation known as thermal runaway, where the battery temperature increases uncontrollably, potentially causing fires.

Reduce Performance: High temperatures can temporarily reduce the battery’s ability to hold a charge and its overall performance, making your scooter less reliable during hot days.

Tips to Protect Your Electric Scooter in High Temperatures

Park in the Shade: Whenever possible, park your electric scooter in a shaded area. Direct sunlight can significantly raise the temperature of both the scooter and its battery, exacerbating the risk of overheating.

Avoid Overcharging: Overcharging can generate additional heat. Use a smart charger that stops charging once the battery is full, and avoid charging your scooter during the hottest parts of the day. This practice can help prevent the battery from heating up excessively.

Regular Maintenance: Ensure your scooter is well-maintained. Check for any signs of wear and tear, especially on the battery and wiring. A well-maintained scooter is less likely to experience overheating issues and will generally perform better.

Moderate Riding: Try to avoid riding during peak heat hours. Early mornings or late evenings are the best times to ride during a heatwave. This practice not only keeps your battery cooler but also enhances your comfort and safety.

Proper Storage: If you’re not using your scooter for a while, store it in a cool, dry place. Extreme temperatures, whether hot or cold, can affect battery health. A controlled environment can help maintain the battery’s optimal condition.

Check Battery Health: Regularly monitor your battery’s health using the Battery Management System (BMS) provided with your scooter. This system helps detect any anomalies and provides insights into the battery’s condition, allowing you to address issues before they become serious problems.

Cooling Solutions: Some advanced electric scooters come with built-in cooling systems for the battery. If your scooter has this feature, make sure it is functioning properly. Regular checks can ensure that these systems are effectively managing the battery’s temperature.

Why Choose Ipower Batteries?

At Ipower Batteries, we understand the unique challenges posed by India’s diverse climate. Our lithium battery packs for 2W and 3W vehicles are designed with advanced thermal management systems to withstand extreme temperatures. Here’s why our batteries are the best choice for your electric scooter:

Advanced Thermal Management: Our batteries are equipped with cutting-edge technology to manage and dissipate heat effectively, ensuring optimal performance even in high temperatures.

Durability and Reliability: Designed to endure the harshest conditions, our batteries offer superior performance and longevity. Whether you’re navigating the scorching streets of Jaipur or the humid lanes of Chennai, our batteries are built to last.

Safety First: With multiple safety features, including overcharge protection, short-circuit protection, and thermal runaway prevention, our batteries ensure your ride is safe. Safety is our top priority, and our batteries are engineered to provide peace of mind.

Summing up

Keeping your electric scooter safe during the scorching Indian summer requires a combination of preventive measures and choosing the right battery. By following the tips outlined above and opting for Ipower Batteries, you can ensure your electric scooter remains in optimal condition, providing you with a reliable and eco-friendly mode of transportation.

Stay cool, stay safe, and keep riding!

Charge Your EV Smartly: Be a Smart EV User

Electric vehicles (EVs) are revolutionizing the transportation landscape, offering a sustainable alternative to traditional fuel-powered vehicles. As an EV owner in India, charging your vehicle efficiently is crucial to maximizing its benefits. This blog will guide you on how to charge your EV smartly, considering factors such as variable tariffs, high and low power load timings, and other essential tips.

Understanding Variable Tariffs in India

In India, electricity tariffs can vary based on the time of day. Understanding these variable tariffs can help you save money while charging your EV.